Today we are writing a systematic and practical guide for small jewelry entrepreneurs, focusing on "How to Choose and Cooperate with Jewelry Manufacturers". It includes directly implementable processes, data models, cost estimation and risk control checklists, and recommends 10 jewelry manufacturers from China.

How to choose and work with a jewelry manufacturer

How Small Jewelry Brands Can Efficiently Work with Manufacturers (with Data Models & Practical Checklists)

I. Who This Guide Is For & What You’ll Gain

Target audience:

Small jewelry brand owners preparing to launch via DTC / independent websites / platforms (Etsy, Shopify, TikTok Shop, Amazon Handmade), micro-businesses, live-stream sellers, or designer-led labels.

You will learn:

Hard criteria for selecting manufacturers

3 starter ordering strategies with cash flow models

Cost calculation for 4 common materials

A step-by-step SOP from sampling → mass production → inspection

Compliance & certification essentials

Email templates & negotiation checklist for working with Chinese suppliers (incl. OKA Accessories)

Risk scenarios & countermeasures

II. Common Supply Models for Small Brands

Mainstream cooperation: OEM (your design/sample → production) & ODM (factory’s design library → customization).

For small MOQs:

ODM first – lower development cost, faster sampling, lower risk.

OEM later – when you have a validated bestseller concept or brand/IP collaboration.

Factory types:

Vertical factories – in-house design → mold → casting → polishing → plating → packaging. Better quality/lead time control, but often higher MOQ.

Integrator trading firms/studios – coordinate multiple factories, more flexible, lower MOQs, great for new product testing.

III. 10 Hard Criteria for Choosing a Manufacturer

MOQ (Minimum Order Quantity) – aim for 100–300 pcs/style; allow mixing colors.

Material expertise – 925 silver, brass, 316L stainless steel, alloys; setting methods (prong/pave/micro) & finishing (PVD, gold/rhodium plating).

Sampling speed – standard 5–10 days; complex stone settings/3D wax: 10–15 days.

Yield rate – ≥97% in mass production; below this means process risks.

Lead time stability – 20–35 days typical; plan ahead for peak season.

Transparent pricing – list materials, plating thickness, findings, labor, wastage, packaging, QC, freight separately.

Compliance ability – Nickel, lead, cadmium limits; REACH, CA Prop 65, nickel-free earring posts available.

Polish & plating consistency – ask for plating thickness reports & salt-spray/sweat test results.

Small order flexibility – ability to combine styles/colors; quick replenishment ≤15 days.

Communication & after-sales – dedicated contact, issues closed within 48h, repair/rework possible.

IV. Cost Structures & Reference Data

Reference EXW factory prices in China (USD/pc), to help with margin planning:

| Material & Process | 200 pcs | 500 pcs | 1000 pcs | Notes |

|---|---|---|---|---|

| Brass + 18K plating (basic earrings/necklaces) | 2.2–3.8 | 1.8–3.2 | 1.5–2.8 | Plating 0.1–0.3μm, upgradeable to 0.5–1.0μm |

| S925 Silver + Rhodium/Gold plating | 4.0–7.0 | 3.2–6.0 | 2.8–5.2 | Silver price fluctuation key factor |

| 316L Stainless Steel + PVD | 1.6–3.0 | 1.3–2.5 | 1.1–2.2 | Strong durability, good for entry lines |

| CZ pave/complex multi-component | 5.5–10.0 | 4.5–8.5 | 3.8–7.2 | Higher labor & wastage costs |

Additional costs:

Sampling: $30–$120/style (deductible against production).

Mold: $50–$150 (simple), $150–$400 (complex 3D).

Packaging: $0.15–0.60/pc.

3rd-party inspection: $180–$300/batch.

Freight:

Express (100–200 pcs): $6–10/kg

Air cargo: $3–6/kg

Sea LCL: $80–180/cbm (destination fees extra).

Duties/compliance: 3–8% buffer for tax/misc.

Margin back-calculation example:

316L necklace, factory $2.0 → packaging/logistics/wastage $0.6 → landed cost $2.6.

Retail: $19–29.

Target gross margin: 70–80%; for marketplaces + ads, ≥75% safer.

V. Three Starter Order Strategies

A. “Small-batch, multi-style” test (recommended)

MOQ: 100–150 pcs/style × 6–10 styles.

Goal: validate aesthetic, price elasticity, marketing conversions.

Timeline: Week 1 select, Week 2–3 samples, Week 4–6 launch.

Success metric: Within 3 weeks, if repurchase & ROI >1 → replenish.

B. “Hero + supporting” dual structure

1–2 hero styles × 300–500 pcs, plus 6–8 supporting styles × 80–120 pcs.

Works if you already have influencer/fan base; double down on hero SKUs.

C. “Evergreen + seasonal” mix

70% timeless basics (hoops, snake chains, initials), 30% holiday/gift styles.

Holiday items must be pre-sold or very small batches.

Replenishment rhythm:

With 21 days production + 7 days transit, safe stock = 28 days demand ×1.2 safety factor.

For 100 pcs/week sales → ~336 pcs buffer. Use biweekly rolling reorders.

VI. Sampling → Mass Production SOP

Requirement sheet (one-pager) – drawings, sizes, materials, plating, settings, logo placement, accessories, packaging, compliance.

Sampling – 3D render → wax/3D print → metal sample. Track revisions & tolerances.

Confirmation standards – plating color swatches, plating thickness (Au 0.3–0.5μm, Ag/Rh 0.05–0.1μm), size ±0.2–0.3mm.

Pre-production run – 20–50 pcs test for assembly/fit.

In-line QC – pre- & post-plating inspections. AQL 2.5 (major), 4.0 (minor).

Durability tests – salt/sweat 24–48h, no obvious fading; stone pull 4–6N min.

Final QC – surface defects, welds, plating, logo, pairing. Key parts tested separately.

Retention samples & traceability – 2–3 pcs each side, with plating/lot records.

VII. Compliance & Sustainability Essentials

Heavy metal restrictions: Nickel release, lead, cadmium. REACH (EU), CA Prop 65 (US).

Hypoallergenic: S925, 316L, nickel-free posts.

Sustainability: Recycled silver/brass, eco packaging, basic carbon statements.

Labeling: Material stamp (S925), origin, warnings (children/sharp parts).

VIII. Practical Guide with Chinese Suppliers (Case: OKA Accessories)

Company overview:

Qingdao OKA Arts and Crafts Co., Ltd (OKA Accessories), founded in 2013, serving European/American brands and e-commerce sellers with OEM/ODM jewelry.

Highlights:

Small order friendly: MOQ often 200–300 pcs/style.

Sampling & lead time: 5–10 days samples, 25–35 days bulk.

Core materials: S925, brass, 316L.

Capabilities: PVD/gold/rhodium plating, electro-coating, pave/prong setting, laser logo, gift packaging.

Value-add: Custom packaging, sample photography, basic compliance advice, mixed-style batching.

Negotiation Checklist

Tiered pricing (200/500/1000 pcs).

Plating thickness & weight in PI.

Yield & replenishment lead time ≤15–20 days.

Defect handling (rework/refund % & timeline).

Retention samples & rework responsibility.

Payment: 30% deposit + 70% pre-shipment. RMB/USD both.

Logistics: EXW/FOB/CIF clarified.

IX. Common Risks & Countermeasures

Color batch variance → Lock gold tone range (L*/b*) in PI; compare to master sample.

Fading complaints → State plating thickness (μm) + salt/sweat test reports; add care cards.

Parts mismatch → Pre-assemble earring backs/posts, chain clasps/loops.

Delays → Use rolling delivery (ship 60–70% hot SKUs first).

IP/copyright issues → Avoid blatant copies; file designs, sign NDA.

Cash flow squeeze → Use Strategy A small-batch test + pre-sale to balance inventory.

X. Building Bestsellers & Sales Channels

Pricing tiers: $19–29 (brass/316L basics), $29–59 (S925/stone settings), $59–99 (gift sets).

Content: Unboxing, close-up try-ons, anti-tarnish/hypoallergenic demos.

Bundles: Necklace + studs sets, stacking packs to raise AOV.

Holiday calendar: Valentine’s, Mother’s, Graduation, Black Friday, Christmas (prep 45–60 days ahead).

Retention: Warranty card + 15% discount code; email collection for pre-sales.

XI. Printable Checklist

Define material range (316L / Brass / S925).

Use ODM for test launch, 6–10 styles × 100–300 pcs each.

Prepare full requirement sheet incl. plating thickness (μm).

Shortlist 2–3 suppliers, request samples (include OKA Accessories).

Apply AQL 2.5/4.0 inspection, 24–48h salt/sweat tests.

Include lead time, replenishment, rework in PI.

Build rolling reorder + safety stock model.

Dual-track line: evergreen + seasonal.

Ensure heavy metal/nickel compliance.

Retention samples & after-sales SOP.

XII. FAQ

Q1: Can I start with $3,000?

Yes. 8 styles × 120–150 pcs × $1.5–3.5 EXW, plus samples/molds/packaging/logistics, total $3,000–4,500 is realistic.

Q2: How to reduce tarnish complaints?

Use 316L+PVD or S925+Rhodium; plating ≥0.3–0.5μm; add care guide; in humid regions, request protective e-coating.

Q3: What about allergic reactions to earrings?

Offer nickel-free posts, S925 posts, or titanium. Label hypoallergenic. Provide spare anti-allergy backs.

Q4: Should I start with S925 or Stainless Steel?

Depends on budget/target. For cost efficiency & durability: 316L. For premium feel & positioning: S925.

Conclusion

For small jewelry brands, a “small-batch, multi-style, fast-reorder” strategy plus quantifiable quality & lead time metrics beats large risky orders.

Choosing partners like Qingdao OKA Arts and Crafts Co., Ltd (OKA Accessories) — small-order friendly, full-process capable, responsive — helps reduce trial costs and shorten idea-to-market cycles.

Apply this guide’s cost tables, SOPs, and negotiation checklist and you’ll be ahead of most new entrants. May your first batch already deliver a breakout style and healthy rolling cash flow!

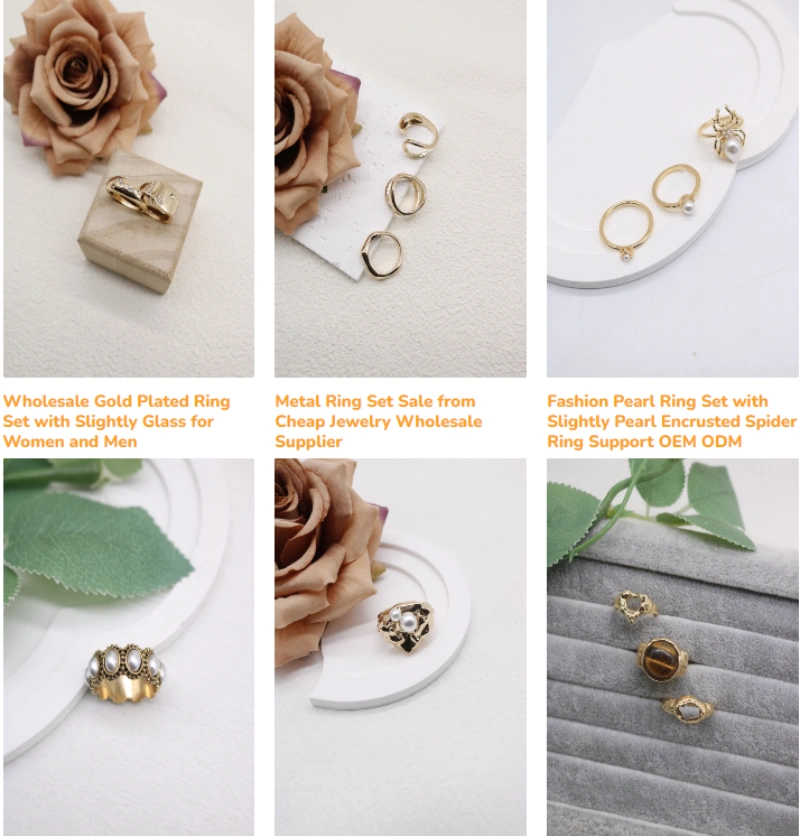

Top 10 jewelry manufacturers for small businesses from China

Here’s the English version of the article with the 10 recommended jewelry manufacturers for small businesses, including Qingdao OKA Arts and Crafts Co., Ltd (OKA Accessories):

1. Qingdao OKA Arts and Crafts Co., Ltd (OKA Accessories)

Founded in 2013, with extensive OEM experience for UK and Korean brands. They have a design center in London and factories in Qingdao and Yiwu

Serve clients in over 50 countries, including well-known brands like Pull&Bear, Urban Outfitters, PrettyLittleThing (okaaccessoriescn.com).

Strengths: Low MOQ (around 200 pcs), high monthly sample capacity, 98% lab pass rate, 97% on-time delivery rate.

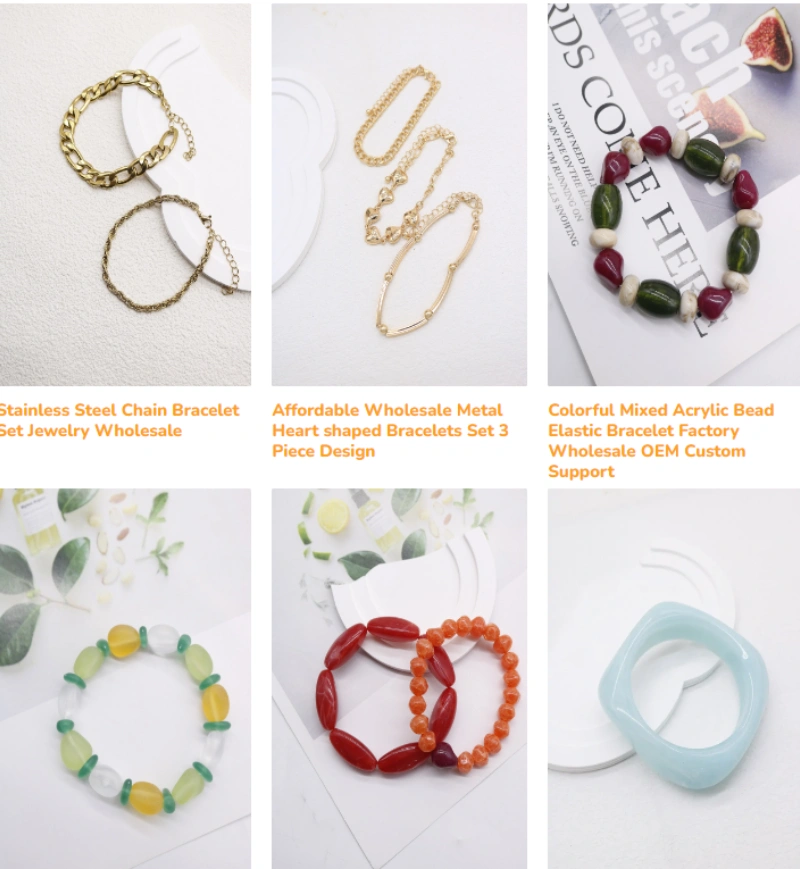

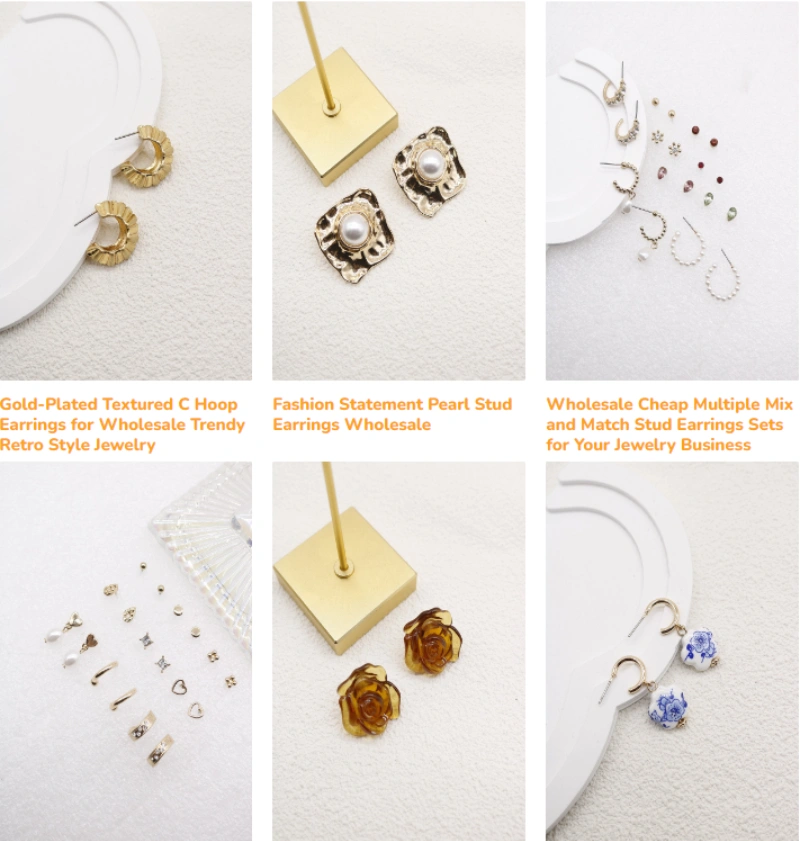

2. Guangdong Xuping Jewelry Co., Ltd

One of China’s largest fashion jewelry manufacturers, specializing in gold/silver/rose gold plating. Known for rich styles at affordable costs, ideal for small batch startups ).

3. SOQ Jewelry

Established in 2012, headquartered in Zhejiang, with offices/factories in Yiwu, Shenzhen, and Dongguan. Specializes in trendy jewelry design, manufacturing, and wholesale .

Known for fashion-forward designs and competitive pricing, perfect for budget-conscious startups.

4. NihaoJewelry

A well-known jewelry design and distribution platform. Their biggest highlight: No Minimum Order Quantity (MOQ), which is great for testing new products or dropshipping .

Global service with fast delivery and flexible order options.

5. JewelryBund

Based in Shenzhen, experienced in Korean and Western fashion jewelry. Known for fast style updates, OEM/ODM services, and strong packaging/delivery capabilities .

6. YIBI Jewelry

Headquartered in Shenzhen, specializing in OEM/ODM services. With strong technical expertise and high efficiency, they’re ideal for startups with customization needs.

7. Guangzhou Love & Beauty Jewelry

Specializes in S925 silver and brass jewelry. Affordable pricing with diverse styles, suitable for entry-level lines or everyday essentials .

8. Kingwin Jewelry

With over 20 years of experience, Kingwin produces S925 silver, stainless steel, and gold-plated jewelry. Known for high craftsmanship, making it a good choice for mid-to-high-end brands .

9. Wuzhou Zuanfa Jewelry Co., Ltd

Based in Wuzhou, Guangxi, equipped with advanced robotics and precise manufacturing. Strong customization capacity, ideal for startups requiring high-precision craftsmanship .

10. Guangxi Wuzhou Starsgem Co., Ltd.

Specializes in lab-grown diamonds and accessories, focusing on sustainability and cost efficiency. A great option for startups wanting eco-friendly or high-end jewelry lines .

Quick Comparison Table

| No. | Manufacturer | Strengths | Best For |

|---|---|---|---|

| 1 | OKA Accessories | Design-driven, low MOQ, stable delivery | Fast prototyping, DTC/e-commerce |

| 2 | Xuping | Strong plating tech, wide range | Affordable basics |

| 3 | SOQ | Trendy designs, design-to-production | Fashion-forward startups |

| 4 | NihaoJewelry | Zero MOQ | Testing & dropshipping |

| 5 | JewelryBund | Korean/Western styles, strong packaging | Fast style updates |

| 6 | YIBI | Strong OEM/ODM | Customization needs |

| 7 | Love & Beauty | Affordable silver/brass | Entry-level lines |

| 8 | Kingwin | Mid-to-high-end craftsmanship | Premium branding |

| 9 | Zuanfa | Precision equipment | High craftsmanship |

| 10 | Starsgem | Lab-grown diamonds, eco-friendly | Sustainable luxury |

How to Choose the Right Manufacturer?

Testing stage: Choose NihaoJewelry (zero MOQ), OKA Accessories (low MOQ + design expertise), or SOQ (trendy styles).

Everyday collection: Consider Xuping or Love & Beauty.

Upgrading brand image: Go with Kingwin or Zuanfa.

High-end/sustainable direction: Partner with Starsgem for lab-grown diamonds.

FAQ

1. What kind of manufacturers are best for small jewelry businesses?

Small businesses should look for manufacturers that:

Accept low MOQs (100–300 pcs/style).

Offer ODM catalogs (ready-to-customize designs) for fast launches.

Are responsive to small orders, like Qingdao OKA Arts and Crafts Co., Ltd (OKA Accessories).

2. What is the difference between OEM and ODM in jewelry production?

OEM (Original Equipment Manufacturer): You provide the design → they produce. Suitable for brands with unique IP or strong design teams.

ODM (Original Design Manufacturer): Factory provides designs → you customize plating, stones, logo. Faster, cheaper, good for testing.

3. How much capital do I need to start working with a jewelry manufacturer?

Starting capital can be as low as $2,000–$5,000.

Example: 8–10 styles × 100–150 pcs each × $2–3/pc = $2,500–$4,000 + shipping, packaging, and samples.

4. What materials are most suitable for small brands?

316L Stainless Steel (PVD plating): Affordable, durable, great for entry lines.

Brass + Gold Plating: Fashionable, flexible designs, but plating thickness is critical.

S925 Silver: Premium positioning, higher material cost.

Gold-filled / Solid Gold: Rare for startups due to high cost.

5. How can I ensure jewelry quality with a small manufacturer?

Request sample approval before bulk order.

Specify plating thickness (e.g., ≥0.3μm for gold, ≥0.05μm for rhodium).

Conduct sweat/salt spray tests for tarnish resistance.

Apply AQL 2.5/4.0 inspections for defects.

6. What is a reasonable production lead time for small orders?

Sampling: 5–10 days (complex designs: 10–15 days).

Mass production: 20–35 days, depending on materials & factory capacity.

Factories like OKA Accessories typically deliver within these ranges.

7. How do I handle compliance and safety requirements?

Check for:

Nickel-free, lead-free, cadmium-free certification.

Compliance with EU REACH and US Prop 65 standards.

For earrings: request nickel-free or S925 posts.

8. How can I avoid overstocking as a small brand?

Use a “small-batch, multi-style” strategy (100–150 pcs/style).

Test designs → double down on bestsellers.

Set a reorder rhythm: 2–3 weeks lead time + 1.2× safety stock.

9. How do I communicate effectively with a manufacturer?

Send a requirement sheet (drawings, material, size, plating, logo, packaging).

Use clear tiered order inquiries (200/500/1000 pcs quotes).

Confirm all specs in the Proforma Invoice (PI), including defect handling and plating.

10. Which manufacturers are recommended for small businesses?

Some well-known, small-order friendly suppliers:

Qingdao OKA Arts and Crafts Co., Ltd (OKA Accessories) – S925, brass, stainless steel; MOQ 200–300 pcs/style.

Yiwu Jewelry Factories (China) – fast fashion jewelry, flexible MOQs.

Dongguan Stainless Steel Workshops – strong in 316L steel.

Jaipur (India) – gemstone & handmade jewelry.

Bali (Indonesia) – artisan silver.

Istanbul (Turkey) – gold-plated fashion jewelry.

Bangkok (Thailand) – fine jewelry production.

Seoul (Korea) – minimalist trends.

New York / LA (USA) – local, higher cost, faster shipping.

Guadalajara (Mexico) – artisanal silver.